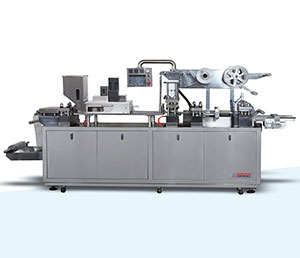

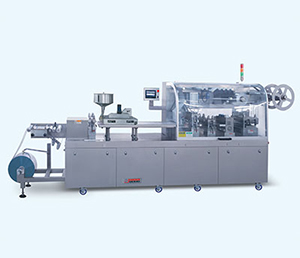

AL-PVC/AL-AL Blister Packaging Machine, DPP-260K/260H

The DPP-260K/260H blister packaging machines, combine frequency conversion, speed regulation with an integrated opto-mechatronics control system, adapted to meet the strict GMP standards of the pharmaceutical industry. The blister packaging machine stands at the forefront of such technology in the domestic market. With its advanced functionality, easy operation, and excellent production capacity, our blister packaging machine ideal for a large and medium-sized pharmaceutical, healthcare, and food enterprises. Thanks to its design and functions, our blister packing machinery is the best choice for efficient and reliable packaging solutions.

Specifications| Model | ||

| Cutting Frequency | AL/Plastic: 20-80 times/min | AL/Plastic: 20-60 times/min |

| Al/AI: 15-30 times/min | ||

| Max. Forming Depth | AL/Plastic: 25mm Al/AI: 18mm (made to order) | |

| Travel Range | 30-120 mm (made to order 30-140 mm) | |

| Clean Compressed Air Pressure | 0.6-0.8Mpa | |

| Air Consumption | 0.25-0.5m³/min (air compressor prepared by user) | |

| Power Supply | 380V 50HZ 10kW | |

| Dimensions | 4775×760×1620cm (detachable) | |

| Weight | 2088kg | |

- The blister packaging machine is equipped with a sophisticated PLC control system, complete with an intuitive touch screen that supports both Chinese and English. This interface enables smooth frequency conversion speed regulation and effortless adjustments via its servo traction system.

- This model of pharmaceutical packing machine is equipped with thermal temperature control and testing, it also includes overload protection and precise positioning testing for PVC and PTP packaging materials. Our packing machine’s intelligent design facilitates automatic fault diagnosis with alarm indications and has an automatic power-off protection feature for enhanced safety.

- The design of the frame of provides excellent visibility, ensuring a safe and convenient operation. Its contact-type heating, positive pressure forming, and air cushion thermal sealing, both upper and lower net, enhance the overall quality of your product packaging.

- The moulds, in the blister packaging machine are designed in a rectangular shape with trapezoidal positioning, allow for quick and easy changes. Its contact parts are made from premium stainless steel and aluminum alloy, ensuring durability and a high-quality finish. The machine efficiently sorts finished products, automatically collects any defective items, and includes an easy-to-use waste rewinding system for efficient scrap collection.

- Our blister packing equipment has a special design that makes it easy to move into elevators or workshops, enhancing its practicality in various settings.