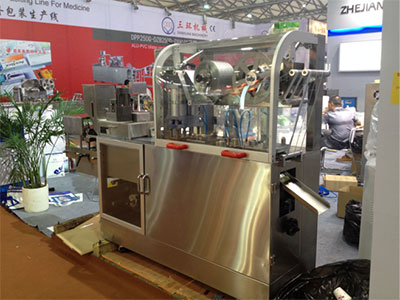

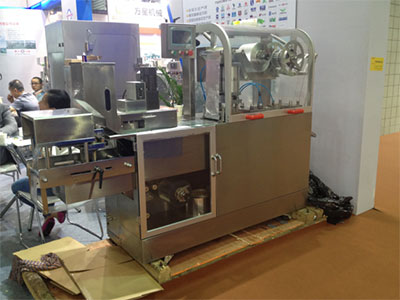

AL-PVC/AL-AL Blister Packaging Machine, DPP-150

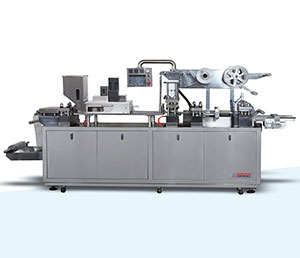

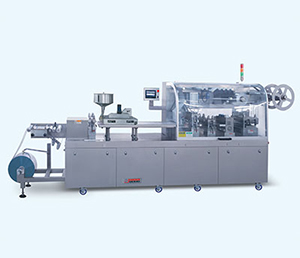

The DPP-150C packing machine is a user-friendly blister packaging machine, perfect for small to medium-sized pharmaceutical companies, health product factories, and hospital pharmacies. It's ideal for producing small batches of various products. This packaging machine automates tasks like feeding materials, forming, heat-sealing, pressing, batch number printing, and punching; easy to use, offering a full range of functions. Furthermore, it is manufactured in accordance to both CE and GMP standards, ensuring quality and safety in production.

Our blister packaging equipment are known for their efficiency and precision in packaging small items like pills, capsules, and other pharmaceutical products. They protect products from moisture, contamination, and tampering, and are crucial for maintaining pharmaceuticals' integrity and shelf life. This type of pharmaceutical packing machine is widely used in the industry due to its ability to quickly and securely package products in a clean and controlled environment.

Applications

The blister packaging machine is designed to meet the diverse packaging needs of several industries. Especially suitable for handling capsules, tablets, honey pills, and candies, as well as liquids like ointments in the pharmaceutical, healthcare, and food sectors. This packaging machinery can also be used for packaging syringes and other irregular-shaped items in both aluminum-plastic and paper-plastic formats.

| Cutting Frequency | AL/PVC: 6-35 times/min; AL/AL: 10-25 times/min. |

| Production Capacity | 2400-7200 blisters/hour |

| Max. Forming Area | 130×130×26mm (standard depth 14mm) |

| Travel Range | 40-140mm (can be lengthened to 160mm according to user's requirements) |

| Standard Sheet | 80×57mm (can be manufactured as user's requirements) |

| Air Pressure | 0.4-0.6 Mpa |

| Air Supply | ≥0.2m3/min |

| Total Power | 380V/220V, 50Hz, 3.6kW |

| Main Motor Power | 0.75 kW |

| PVC Hard Pieces | 0.15-0.5×150 mm |

| PTP Aluminum Foil | 0.02-0.035×150mm |

| Dialysis Paper | 50-100g×140mm |

| Mould Cooling | Tap Water or Circulating Water |

| Overall Dimensions (L×W×H) | 2300×560×1410mm |

| Weight | 750kg |

Due to the advanced technology, this blister packaging machine passed the identification of scientific and technological achievements in Zhejiang Province and was ranked as national key new product. Meeting requirements of GMP, this machine has been sold to domestic and international pharmaceutical factories and large and medium-sized hospital, and has been exported to India, Pakistan, Malaysia, Burundi, Hong Kong, Taiwan and other countries and regions.

With small volume, light weight and compact structure, the AL-PVC or AL-AL blister packaging machine is easy to operate and convenient to maintain. Adopting frequency stepless speed regulation, the machine has a maximum blanking frequency of 35 times per minute and the stroke can be adjusted within 40-110mm. Our product uses plate-type mould and positive pressure forming. It will automatically stop and alarm when the tablet is broken or runs out. A universal feeder is optional and its filling ratio is over 99.5%. The feeder can be equipped with a suction inlet to eliminate the dust problem arising in the feeding process.