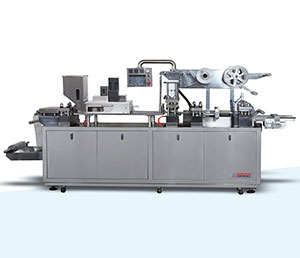

AL-PVC/AL-AL Blister Packaging Machine, DPP-80

Applicable to pack capsules, pills, tablets, health care products, candies, hardware and other items, the DPP-80 AL-PVC or AL-AL blister packaging machine is widely used in small pharmaceutical factories, hospital preparation rooms, drug research institutes, small pilot plants, etc.

With a plate structure, the AL-PVC or AL-AL blister packaging machine adopts helical gear reducer, which runs stably and has low noise and long service life. Plate size can be changed at will and items of any shape can be packed, such as elliptical, triangular, square, etc. In addition, this machine is easy to operate and convenient to maintain.

Specifications| Cutting Frequency | 10-30 times/min |

| Max. Forming Areas | 105×70mm |

| Travel Range | 20-110mm (can be manufactured as user's requirements) |

| Standard Sheet | 80×57mm (can be manufactured as user's requirements) |

| Air Pressure | 0.4-0.6Mpa |

| Total Power | 380V/220V 50Hz 2.8kW |

| Main Motor Power | 0.75 |

| PVC Hard Pieces | 0.15-0.5×110mm |

| PTP Aluminum Foil | 0.02-0.035×110mm |

| Dialysis Paper | 50-100g×110mm |

| Mould Cooling | Tap Water or Back Water |

| Overall Dimensions | 1840×590×1100mm |

| Weight | 350kg |

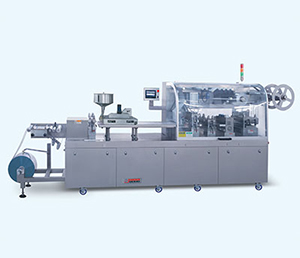

- This blister packaging machine is equipped with the latest high-power transmission technology in the domestic market, using a row chain for movement. This smart design effectively cuts down on the usual errors and noise you'd get with gear transmissions.

- It's equipped with an imported electrical control system. For those who need it, there's the option to add features like detecting leaks in the fill process or a system to remove any tablets that are missing.

- The blister packaging machinery has a modular setup that really streamlines packaging. It starts with shaping PVC, then moves to feeding and heat sealing. Next, it does tropical aluminum cold forming followed by another round of heat sealing, and finishes with punching – all these stages are smoothly integrated into one process.

- Our blister packing machinery is also equipped with a photoelectric control system for precise coordination. It feeds PVC, PTP, and tropical aluminum packaging materials automatically and comes with a device to collect scrap automatically. This ensures a stable and in-sync operation through each stage, especially during long production runs.