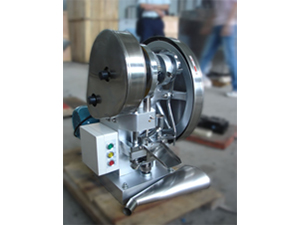

Single Punch Tablet Press Machine

Single punch tablet press machine is a small desktop type product for electric and continuous sheeting, providing the function of pressing all kinds of granular raw materials into round ones. It can be available in labs for trial production or low volume production of various types of tablets, sugar pills, calcium tablets, pills of abnormal shape and so on. Besides, this device is allowed to adjust the depth of the filling material and the thickness of tablets, which can also fit into stamping die.

Specifications| Item | TDP-5 |

| Maximum Pressure of Tablet | 50KN |

| Maximum Diameter of Tablet | 22mm |

| Maximum Depth of Fill | 15mm |

| Maximum Thickness of Tablet | 7.0mm |

| Production Capacity | 3000pc/h |

| Power of Electromotor | 750W |

| Revolving Speed of Electromotor | 1400r/min |

| Voltage of Electromotor | 380V |

| Frequency of Electromotor | 50Hz |

| Overall Dimension | 600*500*700mm |

| Net Weight | 150kg |