Capsule Polisher (with Sorting Function)

Capsule sorter polisher can be available in all kinds of capsules with no need for replacing molds. It is not only suitable for eliminating static electricity and polishing capsules and tablets, but also used to automatically weed out the capsules which possess minor loading, empty shell, fragments and the separated body caps.

Moreover, this capsule sorter polisher is characterized by small volume, attractive appearance, adjustable height and tilt angle of machine as well as the ability of connecting with any type of capsule filling machine for use. It truly realizes timely production and polishing to improve the polishing quality and production efficiency.

To comply with the GMP requirements, our capsule sorter polisher adopts stainless steel inside medicine polishing room. If equipped with fast connection elements, it will be more convenient to disassembly and more thorough to clean. Besides, this machine comes with security protection system and its motor rotation speed is controlled by frequency converter. Thus, our product is able to continuously work with the capacity of bearing large starting torque.

Specifications| Production Efficiency | Max. 70000 capsules/min |

| Application Range | Various capsules |

| Power Supply | 220V 50/60Hz |

| Weight | 45kg |

| Total Power | 0.18kW |

| Vacuum Dust-Intake | 2.7m³/min |

| Compressed Air | 30pa |

| Dimension (L*W*H) | 900×600×1100mm |

| Auxiliary Equipment | Dust Collector (1pc) |

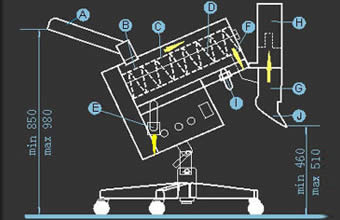

Firstly, the capsule filling machine transports these filled capsules to the chute entrance of polisher A. Then, the capsule is delivered by rotating bushes from the entrance B to the sieve tube C. In the sieve tube D, bushes help polish and clean the capsule surface, which also serve to recycle the scattered materials without body caps through vacuum suction mouth E. Then, brushes send the capsule to the export of sieve tube F. After that, the capsule sorter polisher G helps collect the capsules which have minor loading, empty shell, fragments and separated body caps into the container H by means of clean compressed air. The pressure of compressed air displays on the pressure gauge I of filter regulator with adjustable function in accordance with different requirements. Finally, those qualified capsules can be sent out from the exit.