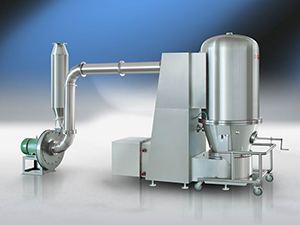

AL-PVC-AL Blister Packaging Machine

Adopting advanced technology at home and aboard, the DPP-250E2 AL-PVC-AL blister packaging machine can complete the three different packaging of AL-plastic, AL-AL and AL-plastic-AL, enabling the machine to have a wide range of applications.

This blister packaging machine adopts imported variable frequency governor and the domestic latest model of high-power transmission mechanism. The main driving axle is driven by multiple rows of chains, eliminating error and noise caused by gear transmission. Adopting photoelectric control system, the packaging machine is equipped with PVC, PTP and tropic aluminum feeding unit and automatic scrap rewinding unit, ensuring synchronization stability of ultra-long distance and multi-position.

Specifications| Productivity | 40000-400000 pcs/h |

| Punching frequency | 15-40 times/min |

| Stroke adjustable range | 40-130mm |

| Max. forming area and depth of PVC | 240×120×18mm |

| Width of wrapper | Tropic Aluminum: 250mm Aluminum foil: 250mm |

| Max. forming area and depth of tropic Aluminum | 220×110×20mm |

| Heating plate power | 2kw (Upper), 2kw (Lower) |

| Heat sealing power of AL-PL | 1.5kw |

| Power of stepper motor | 1kw |

| Power of main motor | 2.2kw |

| Heat sealing power of tropic aluminum | 3kw |

| Volume flow of air compressor | ≥0.6m² /min (self prepared) |

| Overall dimensions | 395×760×1820mm |

| Size of encasement | 1550×760×1820mm |

| Weight | 1800kg |

The blister packaging machine adopts subsection design. One section includes PVC forming, feeding and heat sealing, and the other section includes tropical aluminum cold forming, heat sealing and punching. These two sections can be packed separately. In addition, material shortage detection device and granule missing detection and rejection device can be configured according to customers' demand.