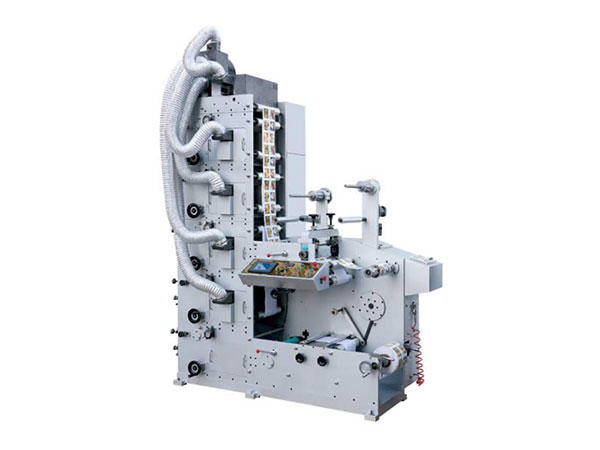

Flexo Printing Machine With Die Cutting

YR-II series flexo printing machine with die cutting is based on advanced flexo graphic advice as well as domestic and foreign process. It can be extensively applicable in wine, tobacco, medical and other industries for adhesive packaging and printing.

Specifications| Applicable material | Roll materials such as paper, film, aluminum foil, etc. |

| Printing color | 1-6 |

| Max unwinding/rewinding diameter | 550mm |

| Unwinding/rewinding shaft core | 3 inch |

| Reel material width | 70-330mm |

| Printing width | 60-320mm |

| Printing length | 175-355mm |

| Max printing speed | 60m/min |

| Overprint accuracy | ±0.15mm |

| Printing plate thickness | 0.38mm |

| Adhesive tape thickness | 1.7mm |

| Max die-cutting area | 350*320mm |

| Power supply | 380V, 50Hz. 3-phase 4-wire |

| Main motor power | 2.2/3kw |

| IR dryer power | about 2kw/unit |

| UV dryer power | about 5kw/unit |

| Dimensions, L * W * H | about 2200*1150*2700mm, with 5 colors |

| Weight | about 2400-3000kg |

- This flexo printing machine with die cutting features fast print speed, short production cycle, wide application, high economic efficiency, frequency control, great effect of background color, no pollution as well as fast dry spe

- In addition, it utilizes ceramic anilox rollers and transfer ink in order to make color hue equal, rustproof, wearable and long service life. By adoption of plate register function, each print unit is able to print independently.

- Thanks to tension control system in control of air type unwinding and rewinding shafts, our flexo printing machine with die cutting is extremely convenient to load and unload the web material. The tension control system consists of tension sensor, magnetic powder brake, clutch and tension controller.

- Besides, this device is equipped with IR dry system and die cutting station. This device can not only finish the printing and die cutting in one machine, but also accomplish paper feeding, printing, glazing, drying, laminating, die cutting, waste collecting and rewinding at one time.

- Furthermore, optional system includes UV drying system, Mitsubishi tension controller, die cutting, slitting, cross cutting cylinder with cutter as well as video inspecting system.