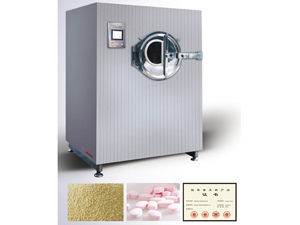

ZP1100 Rotary Tablet Press Machine

ZP1100 rotary tablet press machine is commonly used to manufacture various round tablets or irregular shapes of tablets in pharmaceutical, herbal, chemical and food industries. It features large working capacity, high quality, economical, convenient to operate and monitor, easy to maintain and adjust, long service life as well as rugged and efficient design, etc.

To meet the GMP standard, overall exterior of this product and all parts in contact with tablets are composed of stainless steel. Surface of those parts has been polished and sterilized. If customers require, our company can offer engraving on tablets.

Specifications| Model | ||||

| Number of Station | 39 | 36 | 29 | 24 |

| Tool Type | BB | BB | B | D |

| Max. Diameter of Tablet, mm | 11 | 13 | 18 | 22 |

| Max. Depth of Fill, mm | 18 | 18 | 18 | 18 |

| Max. Capacity, tablet/h | 152,100 | 140,400 | 113,100 | 93,600 |

| Rotary Speed, rpm | 65 | 65 | 65 | 65 |

| Diameter of the Shank, mm | 19 | 19 | 19 | 25.4 |

| Length of Upper or Lower Punch, mm | 133.35 | 133.35 | 133.35 | 133.35 |

| Outer Diameter of the Die, mm | 22 | 24 | 30.16 | 38.1 |

| Height of the Die, mm | 22.22 | 22.22 | 22.22 | 23.81 |

| Max. Pre-Compression, KN | 15 | 15 | 15 | 15 |

| Max. Main Compression, KN | 80 | 80 | 80 | 80 |

| Power of Main Motor, KW | 4 | 4 | 4 | 4 |

| Floor Space, mm | 890 * 820 | |||

| Height with feed hopper, mm | 1800 | |||

| Height without feed hopper, mm | 1650 | |||

| Weight, kg | 1400 | |||

| Control Unit Dimension, L*W*H, mm | 600*370 *900 | |||

| Control Unit Weight, kg | 50 | |||

- Our rotary tablet presses are designed for medium-scale mass production, making them a perfect fit in pharmaceutical, herbal, chemical, and food industries for producing a variety of round and irregular-shaped tablets.

- Their main features include a completely isolated pressing chamber from the gear-driven system, that ensures cleanliness and efficiency. The parts that come into contact with the tablets are either made of stainless steel or have polished and sterilized surfaces. Additionally, the chamber is sealed with organic glass to enhance the working environment.

- These tablet presses have advanced lubrication systems that continuously and thoroughly lubricate the gear system, tracks, and major friction points. Our tablet making machine is user-friendly with a robust build. Operators can easily monitor and adjust operating pressure, thickness, and feeding speeds with conveniently located hand wheels, indicator lights, and control buttons.

- Designed for durability and efficiency, the interchangeable parts of the tablet press feature ease of operation, maintenance, and spare part replacement. The punches and dies are in accordance to IPT international standards, further enhancing their versatility and reliability.