Dry Granulator

The ZKG series of dry granulators stands out for its advanced technology and excellence in pharmaceutical manufacturing. The process starts by meticulously blending prepared powder materials, which are then directed to the hopper. A key feature of this equipment is its unique double-cone, unequal-distance feeding screw, designed to ensure consistent pre-compression at the top of the dual extrusion wheels.

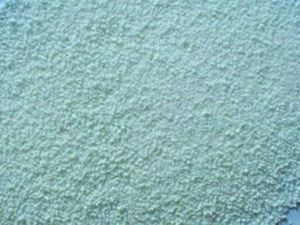

During this essential phase, the material is uniformly compressed from five distinct angles, transforming the powder into compacts (flakes) through the hydraulic-powered extrusion wheels. These flakes can be further processed into particles of specific density, ideal for direct application in tablet compression or capsule filling. This granulation method offers a modern alternative to conventional techniques, significantly reducing energy consumption.

Known for their versatility, these granulators are equipped with adjustable granular specifications and performance, controlled by a PLC system, to cater a range of production requirements and enhancing efficiency. The dry granulating equipment features easy operation and maintenance, minimal noise output, and adaptability, proving to be invaluable in diverse industries such as pharmaceuticals, chemical manufacturing, and food processing.

Specifications| Model | ZKG-10 |

| Max. Capacity | 5-15 kg/h (depends on material density) |

| Granule Size | 10-80 mesh |

| Compaction Roller Size | ∅100×35 mm |

| Compaction Roller Speed | 0-20 r/min |

| Max. Oil Pressure | 12 Mpa |

| Total Power | 3 kW |

| Overall Size | 760×800×1650 mm |

| Weight | 350 kg |