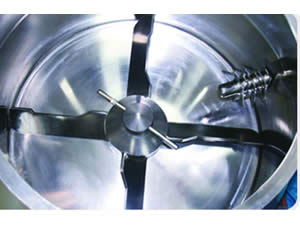

Super Mixer Granulator / High Shear Granulator

The super mixing granulator is suitable for mixing of powder and powder and for granulation of powder and binder in the pharmaceutical, chemical, food and other industries. The whole working process includes mixing and granulating.

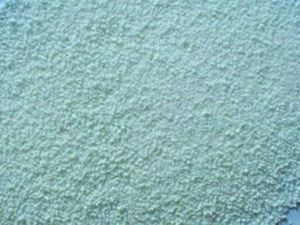

Powdery materials are fed into the material pot through the conical hopper and rotate inside the pot under stirring of the mixing paddle after the hopper is closed. Meanwhile, all materials move along the direction of the conical wall and gradually generate the shape of liquid bridge. Under extrusion, friction and kneading of the paddle and cylinder wall, materials gradually become loose. These soft materials are cut into small and uniform granules in the semi-flow state. After the discharge door is opened, wet granules are discharged under the centrifugal effect of paddle.

Specifications| Model | |||||||

| Working Capacity (L) | 3-35 | 12-35 | 25-70 | 80-120 | 130-180 | 150-240 | 200-360 |

| Batch Time | Mixing: about 2 minutes Granulation: about 7-14 minutes/batch | ||||||

| Agitator Speed (rpm) | 0-700 | 25-500 | 30-250 | 30-250 | 30-220 | 30-200 | 30-170 |

| Agitator Motor Power (kW) | 5.5 | 5.5 | 7.5 | 15 | 18.5 | 22 | 30 |

| Chopper Speed (rpm) | 50-3000 | ||||||

| Chopper Motor Power (kW) | 1.5 | 1.5 | 3 | 4 | 7.5 | 11 | 11 |

| Dimensions (L×W×H) (mm) | 1925×704×1560 | 1935×662×1650 | 2078×702×1800 | 2268×910×2100 | 2600x1000×2300 | 2870×1172×2560 | 2964×1230×2553 |

| Height of Discharge Outlet (mm) | 780 | 796 | 796 | 92o | 985 | 985 | 1162 |

| Machine Weight (kg) | 600 | 584 | 700 | 1111 | 1350 | 1700 | 2000 |

Our super mixing granulator has passed the appraisal of provincial new products and EU CE certification. With consistent programmed technology, this granulator is able to produce granules with stable quality. It can also be manually operated so as to explore technological parameters and process. The conical tank ensures uniform rotation of materials. Water cooling circulation system is mounted in the interlayer at the bottom of the tank. The circulation system has better thermostatic performance than common air cooling systems, thus improving product quality.

The stirring paddle and cutter adopt frequency control, facilitating control of the granule size. A paddle lifting system is available, which makes it more convenient to clean the paddle and pot. The rotation chamber is filled with air and sealed, eliminating dust bonding. The pot cover is automatically lifted and a ladder is attached with this super mixing granulator, making operation easier.