RJWJ-200 Softgel Encapsulation Machine

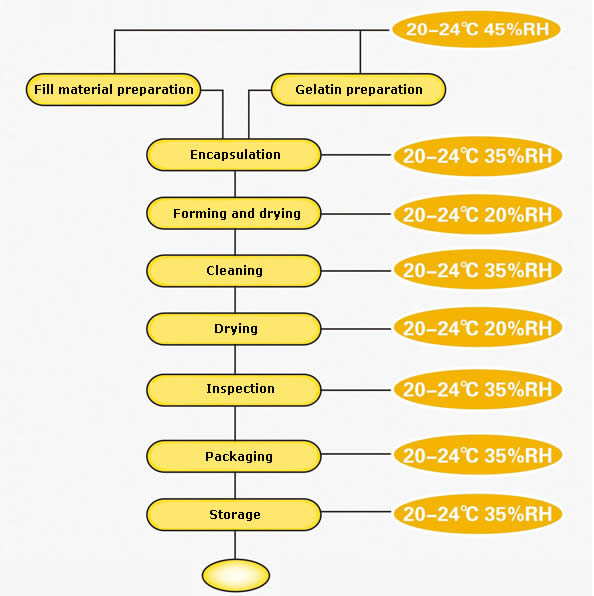

The softgel encapsulation machine efficiently fills capsules with oil-based liquids, suspensions, and pasty substances, producing a variety of softgels in different sizes, shapes, and colors. These softgels are becoming increasingly popular due to their fast disintegration, high absorption rate, attractive design, and ease of swallowing. They are also less prone to oxidation, making them easier to store and carry.

Manufacturers appreciate our RJWJ-200bencapsulation machine for producing high volumes of consistent, high-quality softgels. It is now widely used in the fields of medicine, health products, cosmetics, and even paintball production.

Our pharmaceutical encapsulator has been recognized at the provincial level as a new innovation and has received EU CE certification. It is manufactured using two patented technologies, ensuring quality and precision in every capsule.

Specifications| Model | RJWJ-200 |

| Rotation Speed of Die Roll | 0-5rpm (stepless) |

| Single Plunger Fill | 0-2ml |

| Content Uniformity | ±2% |

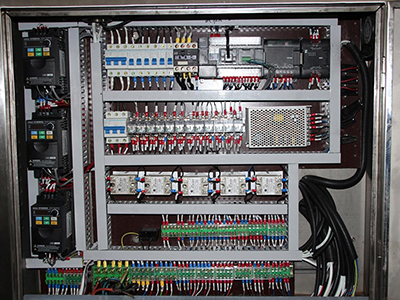

| Main Motor Power | 7kW |

| Plunger Quantity | 12 |

| Overall Dimensions | 1500×950×2000mm |

| Machine Weight | 1000kg |

- This encapsulation machine can produce up to 370 million granules annually (using the 200C model as an example: No.8 oval shape, 3rpm, 24 hours/day, 300 days/year).

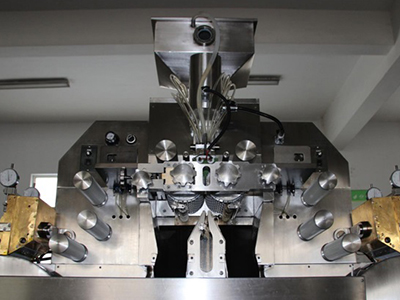

- The medicine injecting part features an advanced linear driving system, ensuring a filling precision of less than ±2%.

- Equipped with an advanced water-cooling system to avoid contamination from air exposure.

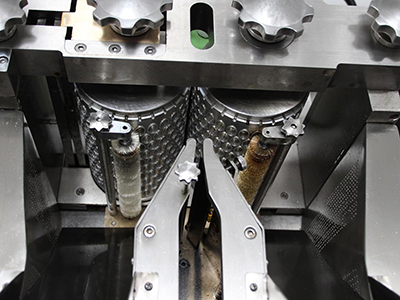

- The encapsulation rate is impressively high, reaching over 98%.

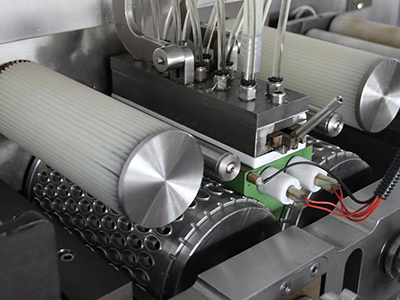

- It uses a minimal oil supply technique for lubricating the gelatin ribbon, drastically reducing oil consumption. This feature is not only cost-effective but also environmentally friendly.

- For instances where printing on the capsules is not required, the encapsulation machine allows using vegetable oil for lubrication, eliminating the need for a subsequent washing process.

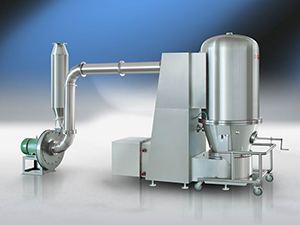

- The capsule transfer equipment includes a food-grade conveying belt approved by the FDA, ensuring non-toxic, non-sticky, and easy-to-clean operation.

- The moulds are crafted from high-quality aviation alloy material, precision-engineered using CNC processing. This ensures longevity and contributes to the machine's overall durability and reliability.

- Its advanced processing and assembly techniques ensure the encapsulation machine’s stable performance, consistent capsule quality, high operational efficiency, and perfect shape. These aspects are critical for maintaining high production standards.

- This softgel encapsulator significantly reduces labor intensity and improves the working environment by featuring an automated system for supplying capsules and materials. This automation aligns with GMP standards, emphasizing the machine's commitment to quality and safety.

- The gelatin box in the machine maintains a constant liquid level, complemented by a dial gauge for easy and accurate rubber thickness adjustments. This feature ensures consistency in capsule quality.

- Equipped with a 1.5kW main motor, the pharmaceutical encapsulation machine operates efficiently even with thicker contents. This power ensures the machine’s uninterrupted performance, a crucial factor for large-scale production.

- All parts of our encapsulation machine that come into contact with the medication and gelatin are made from non-toxic materials. This design consideration prioritizes operator safety and ensures no contamination in the pharmaceutical products, reflecting the machine's high standards in safety and cleanliness.