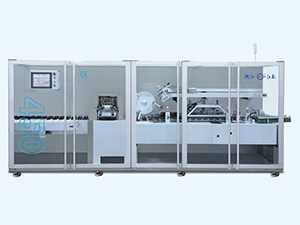

Vertical Cartoning Machine

Developed on the basis of advanced technology at home and aboard, the vertical cartoning machine is a high-tech product integrating mechanics, electronics, light and gas. It has stable working performance and high work efficiency, thus achieving fast cartoning.

This vertical cartoning machine is applicable to automatic feeding and cartoning of various blister-formed or bottled items. The automatic feeding device is convenient to adjust and the plate number can be set freely on the touch screen. The whole process of blister plate detecting, leaflet folding, transmitting and detecting, carton opening and forming, drugs and leaflets loading into carton, batch number printing, carton sealing with paper or hot melt glue, and finished products output is automatically completed.

Specifications| Item | Parameters | |

| Encasing speed | 30-120 boxes/min | |

| Box | Quality requirement | 250-350g/㎡ (Base on the carton size) |

| Dimension range ( L×W×H ) | (65-125)mm × (35-85)mm × (12-50)mm | |

| Leaflet | Quality requirement | 60-70g/ ㎡ |

| Unfolded leaflet specification ( L×W ) | (80-250)mm × (90-170)mm | |

| Fold range ( L×W ) | (1-4) Fold | |

| Compressed air | Working pressure | ≥0.6mpa |

| Air consumption | 120-160L/min | |

| Power supply | 220V 50HZ | |

| Main motor power | 0.75kw | |

| Machine dimensions (L×W×H) | 1380 mm ×1140 mm ×1800 mm | |

| Machine weight | About 1000kg | |

With stable performance and easy operation, our vertical cartoning machine can automatically reject cartons lacking of packaged objects or leaflets. Adopting human-machine operation system and international famous brand of electrical components such as PLC, frequency inverters, etc., the machine will count finished products, display fault, send an alarm, and automatically shut down when overloading.