NJP200C-1200C Automatic Capsule Filling Machine

This capsule filling machine is designed with advanced features for processing both powder and granule medications. It uses a specialized filling system that works intermittently and adjusts speed as needed, making it perfect for automating the filling of capsules. The capsule filler can carry out different processes, from placing the capsules, separating them, filling them, and even removing any that aren't up to standard. It also automatically locks the capsules and ejects the finished product.

The design of this capsule filler includes a fully enclosed turntable that works with high precision and makes very little noise. Our capsule filling equipment is efficient at handling capsules made by standard machines, and its most important parts like bearings and electrical components, come from well-known international brands. This ensures the machine operates smoothly and can work quickly.

Following the strict GMP standards, the automatic capsule filler uses high-quality stainless steel for all parts that come in contact with the medicine. This keeps everything clean and safe.

The capsule filling machine also features a dust collector, which is crucial for maintaining a clean and safe pharmaceutical manufacturing environment.

- The capsule filling machine is designed a compact, energy-efficient design, simplifying mould changes. Its user-friendly design makes it easy to operate and clean.

- The design features a fully enclosed turntable, which solves the problem common in older, open turntable designs where medicine powder can stick to oil over time.

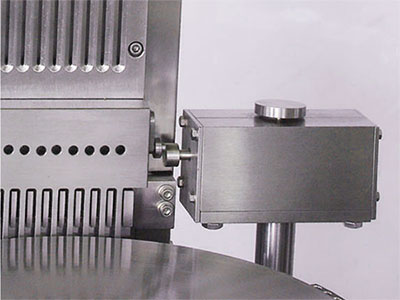

- Additionally, the parts that rotate are completely enclosed, ensuring excellent lubrication. This not only keeps the work surface free of oil but also prevents any cross-contamination with the medicines.

- A key feature of this capsule filler is its lower-positioned cam design, combined with a pressure atomizing oil pump that ensures consistent lubrication inside the cam groove, reducing wear and significantly increasing the lifespan of its parts.

- Another innovative aspect is the barrier around the dosage disk, which effectively recycles any powder shed from the disk's lower plane. This is done through an alternate pipeline, minimizing dust on the work surface.

- The capsule filler is equipped with a Siemens HMI (human-machine interface) and a PLC programmable controller for easy control and operation. This modern technology provides advanced and intuitive control of filling machine, making it highly efficient and user-friendly for pharmaceutical manufacturing.

| Model | ||||

| Capacity (pcs/min) | 200 | 400 | 800 | 1200 |

| No. of mould Bores | 2 | 3 | 6 | 9 |

| Applicable Capsule | 00#-4# | 00#-4# | 00#-4# | 00#-4# |

| Total Power (kW) | 3 | 3 | 4 | 5 |

| Machine Weight (kg) | 600 | 700 | 800 | 900 |

| Overall Dimensions (mm) | 610×670×1600 | 730×950×1700 | 700×900×1800 | 800×1000×1800 |