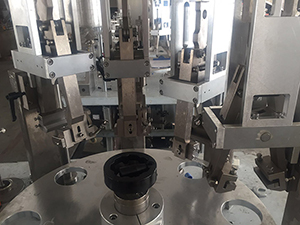

Semi-Automatic Tube Filler Sealer

The aluminum tube filling machine is engineered with a focus on the primary transmission principle, utilizing an indexing mechanism for its rotary table with clamps to achieve intermittent movement. This design allows for efficient execution of tasks such as automatic filling, tail welding, three-side folding, and saddle-shaped sealing. Its versatility makes it a perfect fit for industries like cosmetics, pharmaceuticals, adhesives, and shoe polish, allowing users to easily and accurately adjust the shape and size of the seal according to their specific requirements.

Features- The tube filling sealing machine is user-friendly, offering easy operation and maintenance.

- It's capable of performing a range of tasks, from automatic positioning and filling to welding, cutting, trimming, and code printing, all in one smooth, integrated process.

- Constructed with a stainless steel body, the tube feeder sealer is not only robust but also aesthetically pleasing.

- Its sealing mould can be customized to fit various tube sizes, enhancing its adaptability for different products.

- Running on a pneumatic source, the ultrasonic sealing machine is reliable and built for long-term durability.

- The tube filler's ultrasonic frequency adheres to international safety standards, ensuring it is safe for both human operators and the environment.

- It operates immediately without needing a heat-up period, optimizing efficiency and productivity in the workflow.

| Model | NF-30 |

| Application Range | Cosmetic cream, lotion, gel, toothpaste, sauce, glue and so on |

| Filling Volume | 1-250ml |

| Production Capacity | 1-30 tubes per min |

| Voltage | 110/220/380V customized |

| Power | 750W |

| Weight | 300kg |

| Dimensions (L×W×H) | 1200×820×1650 (mm) |